iamcam - The perfect automated PCB front-end workflow

A new standard for PCB front-end workflow automation

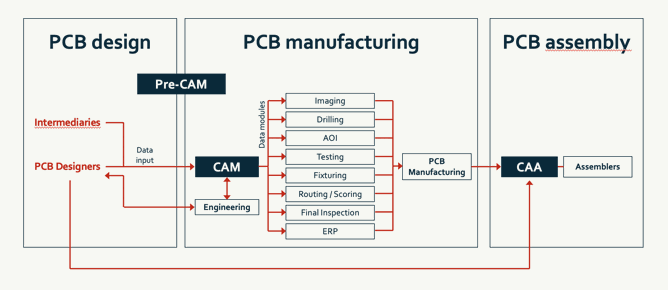

Ucamco's iamcam automates PCB front-end tasks and integrates business systems. This cuts the error rate and the need for operator intervention. It is, by all standards, an exceptional answer to the daily challenges of front-end and production professionals who need to increase quality, reduce errors and drive cost out of the processes. It enables unparalleled workflow automation with rocksolid quality control.

iamcam is highly scaleabe and serves as the heart of any size front-end production operation. It can be configured for simple two to four layer prototype shops, as well as for the most advanced HDI jobs, sequential build, backdrill, flex-rigid.

Seamless integration with 3rd party systems

iamcam comes with extensive business system integration capabilities. It integrates seamlessly with any existing infrastructure (ERP, PPS, website, mail server…). Front-end operators or administration departments can easily interact with the workflow through a transparent user interface. The ERP system can drive the flow of individual jobs, and be driven by it, through iamcam's simple but powerful workflow scripting.

It accepts fabrication data in a wide range of formats, including native CAD formats for Eagle and Altium. It generates data in standards such as PDF, XML and Excel (XLSX).

Compatible with your incumbent CAM system