On-demand InkJet Printing System

Useful Features

CraftPix with numerous functions unique to digitalization

that was not possible with the analog method.

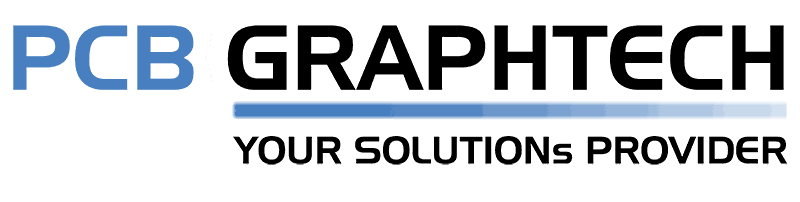

Serialization and Barcode

You can now easily add date, lot code, barcode and serial number to production panels, individual PCBs, test coupons, and other products. This will allow your customers traceability which is just another added value the CraftPix offers. Your choice of man readable, code 39 and matrix barcodes are available.

2D barcode printable with CraftPix series

CraftPix series can print three types of codes: Data Matrix, QR codes and micro QR codes. The area required for printing depends on the number of characters. If printing with CraftPix series, recognition is possible when printed in the same sizes or larger as shown in the table on the right. While the recognition can be done with a 2D barcode reader, it can also be done with the code reading application installed on a cellphone or smartphone.

Minimum print size for 2D barcodes (when droplet volume is 3.5pl).

*Print size will vary depending on the type of text, ink and surface condition of the media.

|

2D Barcode

|

Example

|

10 characters | 20 characters | 30 characters |

| Data matrix (square) |

|

0.03” (0.8 mm)

|

0.039” (1.0 mm)

|

0.047” (1.2 mm)

|

|

Data matrix (rectangle)

|

|

0.047 x 0.023” (1.2 x 0.6 mm) |

0.078 x 0.02” (2.0 x 0.5 mm) |

0.063 x 0.03” (1.6 x 0.8 mm) |

| QR Code |

|

0.051” (1.3 mm)

|

0.055” (1.4 mm)

|

0.055” (1.4 mm)

|

| Micro QR Code |

|

0.039” (1.0 mm)

|

0.039” (1.0 mm)

|

0.043” (1.1 mm) |

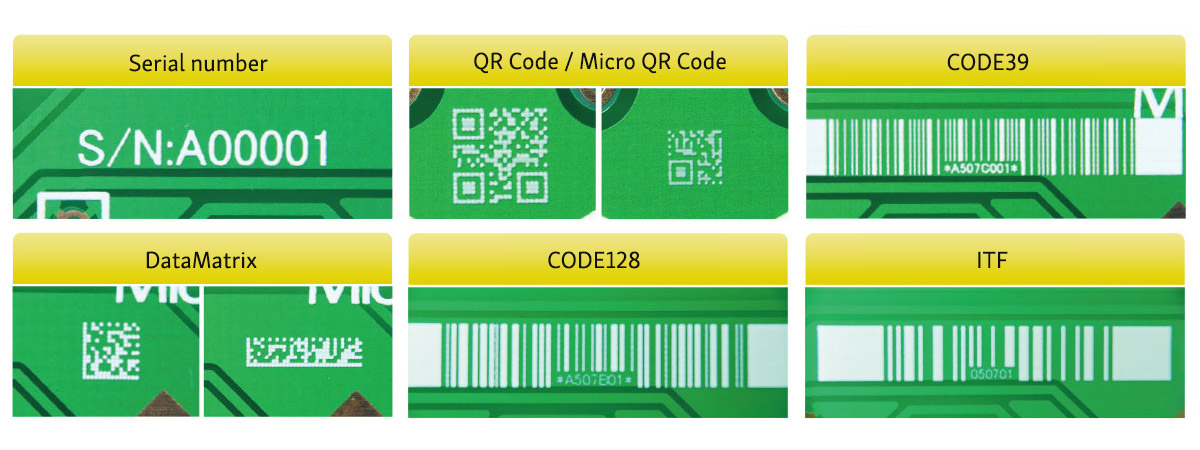

Auto-Alignment

With multiple alignment features available, you can choose from 1 to 4 alignment points. X, Y and theta rotation are measured and data is rasterized for precise image printing. Furthermore, each separate or single-image piece can be aligned with “Piece Alignment”

Auto-alignment makes high-speed and high-accuracy printing possible.

Undivided Area Setting and Gapless Mode

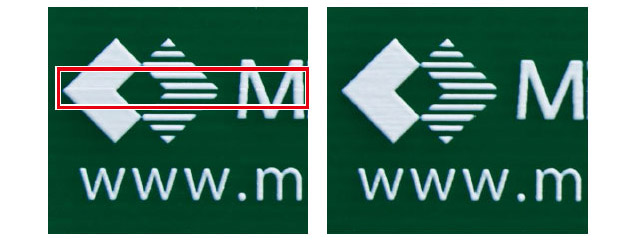

CraftPix series uses approximately 72mm wide print head module therefore, printing is carried out by dividing the image into 72 mm-wideareas from the top. At this time, the border between two divided areas may appear as a subtle line. Normally, this line at the border of the strip is not very apparent; however, depending on the image printed, it may become apparent such as in a logo or solid area. In that case, Undivided Area Feature can be used in order for CraftPix to avoid dividing images or showing of such a line at certain areas.

On the other hand, the gapless mode is very useful feature when printing solder resist ink that requires more number of print passes. This function allows to minimize the effect of evident gap lines throughout the printing panel to ensure very smooth and uniform surface finish. *1

Left: When undivided area is not set

Right: When undivided area is set

*1

Cannot be for area over 72 mm

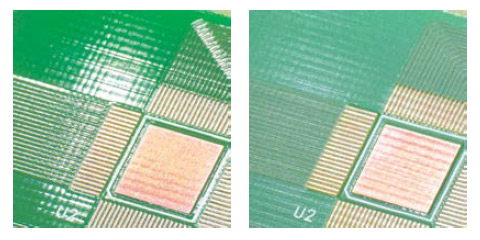

Glossy/Matte Surface Finish

CraftPix can offer two different types of surface finish. When shiny surface is required, our Glossy Surface Finish is suitable. We can assure shinny and smooth glazed surface finish. Bright color tone with high saturation will add showcase very rich appearance to your PCB. In case shiny finish is unrequired, we recommend to use our Matte Surface Finish. Unlike glossy finish, we can offer very calm tone of surface appearance without mirror like shininess.

Left: Glossy Finish

Right: Matte Finish

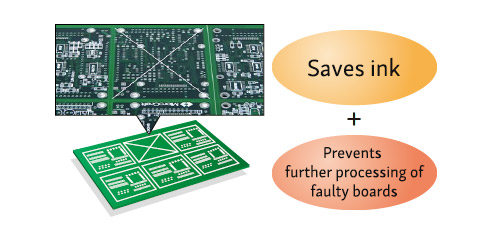

Automated X-Out Printing

Machine can print “X-Out” on the board that contains faults from prior production. This reduces ink consumption by only printing on the necessary panels. Correspondence with serial numbering makes it easy to manage production control. With the barcode option, test results from our EMMA can be sent directly to automatically assign where to print “X-Out”