Key Capabilities

Altium 365

Eliminate Paperwork and Distractions

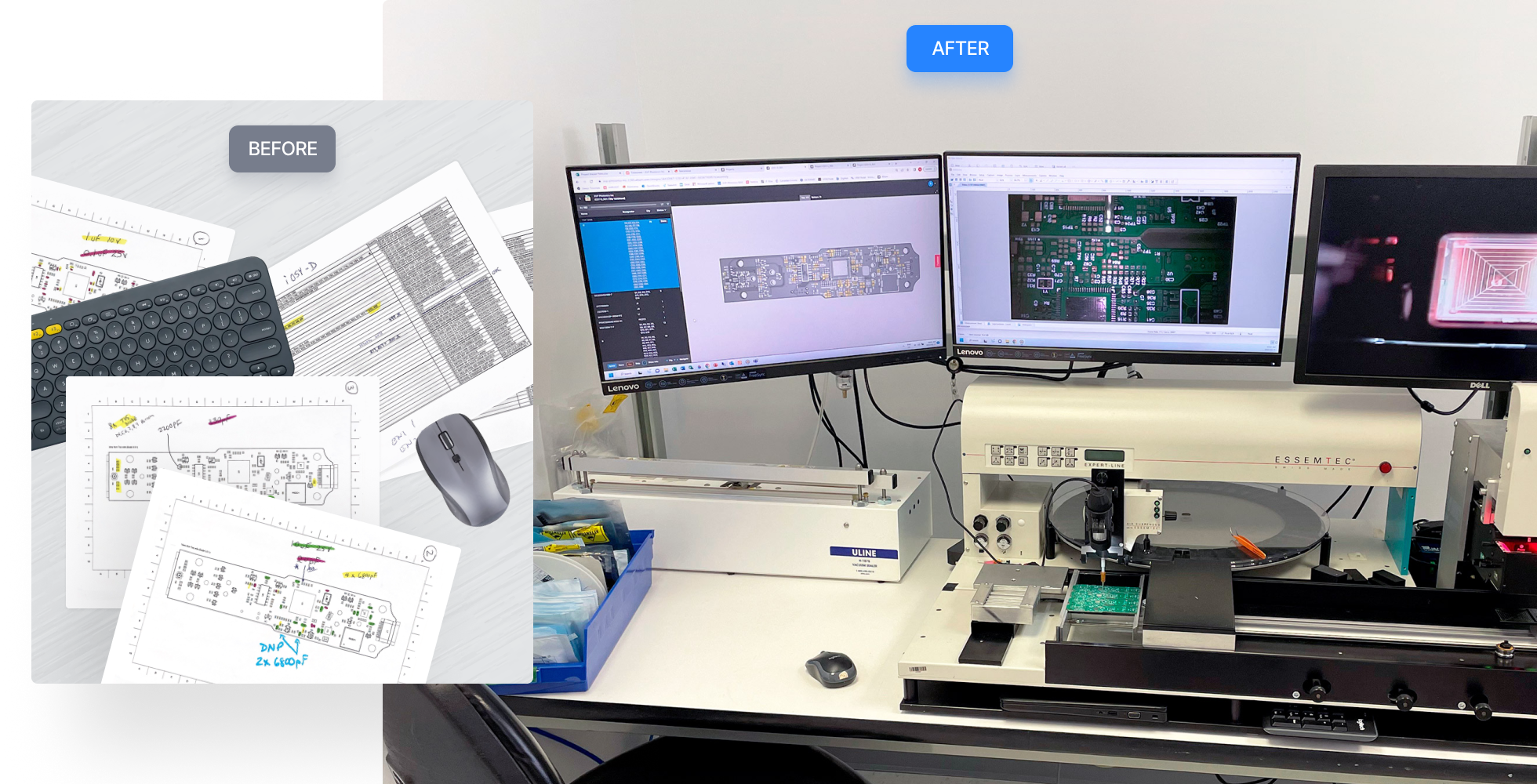

During manual PCB assembly, engineers look at physical paper printouts and design files in the CAD software. To get a full picture, they need to click through different views of the board (2D and 3D) and documents (PCB and BOM). Switching between paper and multiple software interfaces, while holding a hot soldering iron, is inefficient to say the least.

Assembly Assistant brings your Bill of Materials (BOM), PCB Viewer and assembly instructions into one application. Everything you need is in one simple interface!

Altium 365

Accurate Component Placement

Manual component placement and orientation often become error hotspots, especially as shrinking form factors become the standard with SMT packages. Inaccuracy could lead to costly production delays and dreaded re-spins. With the Assembly Assistant, all the components needed to assemble the board (BOM) are displayed on the screen, allowing you to cross-probe from a component to the 2D/3D view of the PCB layout to quickly view the exact physical location, footprint, and orientation of the component on the board.

Altium 365

Easy Navigation, Up-to-date Design Files

Track the progress of the assembly directly with the Assembly Assistant. You can mark each component as you mount it or skip it if necessary. Everything takes place within a connected Altium 365 workspace. Any changes in the design files are propagated to the Assembly Assistant, making sure you are always looking at the latest BOM and board layout.