EMC/EMI issue testing is straightforward and accurate with 3D precision technology.

Used to assist high-density board designers to use off-the-shelf hand-held probes and visualize the root causes of potential EMC and EMI problems during pre and post-EMC compliance testing.

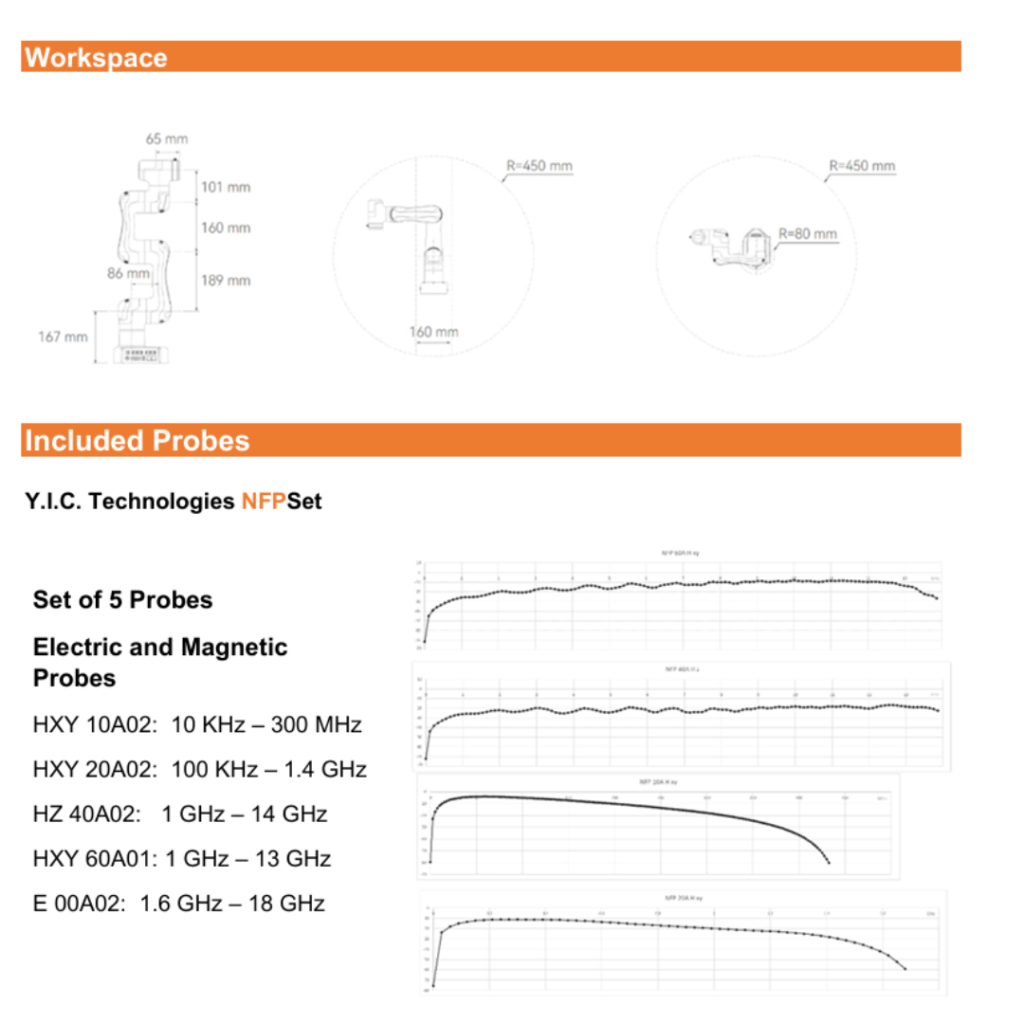

Capability

Spectral scan, spatial scan, peak-hold, continuous scanning, spectral and spatial comparison, scripting, limit lines and report generation.

Supported Spectrum Analysers

Check out the supported spectrum analysers here.

Supported Operating Systems

Windows 11®

Supported overlays:

Picture in JPEG format Standard Gerber© RS274x format and HPGL format CAD files

Max Frequency coverage

Spatial Resolution

Frequency Accuracy of Peaks

Peak marking accuracy of spectrum analyzer

Probe to Probe Uniformity

Dependent on the selected probe

Maximum Radiated Power Load

Dependent on spectrum analyzer and the probe performance

Operating Temperature

From 15⁰ C to 40⁰ C (continuous spectral and spatial scans at 50 MHz)

Net Weight

3.40Kg (Excluding cables and the adaptor)

3D Precision Technology is used to assist high-density board designers to use off-the-shelf hand-held probes and visualize the root causes of potential EMC and EMI problems during pre and post-EMC compliance testing.

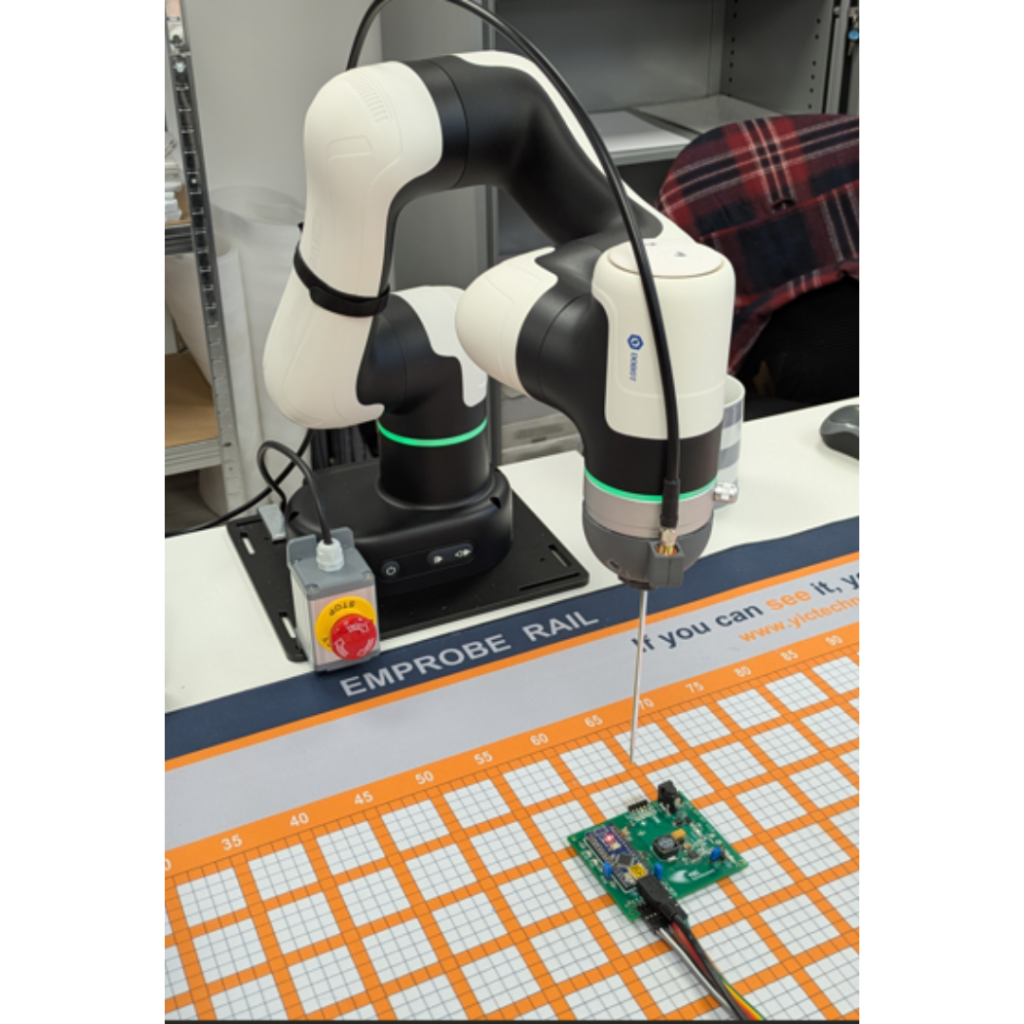

EMProbeE6 enables the PCB and Design Engineers to diagnose EMC/EMI problems using regular off-the-shelf hand-held probes. An easy-to-use Robotic Arm controls the movement of the probe in any direction and an external Spectrum Analyzer provides the results. The EMViewer software is used to control the Robotic Arm and the external Spectrum Analyser collects and analyses the results.

Different types of Robotic Arms can be used, based on the desired size and resolution.

EMProbeE6 delivers repeatable and reliable results that pinpoint the cause of a design failure. As a result, the user can personally test the design without having to rely on another department, test engineer, or time-consuming off-site testing. After diagnosing even an intermittent problem, the engineer can implement a design change and retest. The results provide concrete verification of the effectiveness (or not) of the design change.

The EMProbeE6 solution consists of a computer controlled Robotic Arm, Near Field probes and a customer-supplied spectrum analyser, all controlled by the EMViewer Software.

The EMProbeE6 diagnostic capabilities allow design teams to reduce testing time. Users have also documented 50% reductions in design cycle times. This allows the design team to immediately analyse and compare design iterations